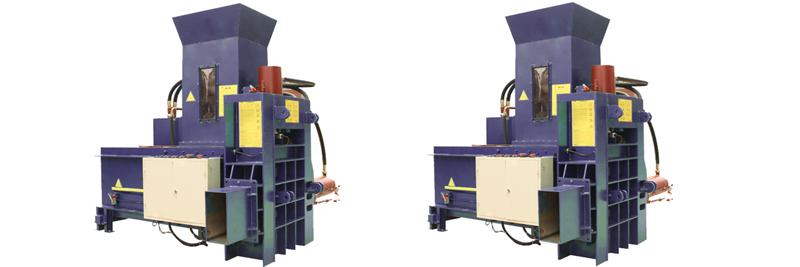

Lehong la Bona Lerōle Baler

NKB240 Wood Saw Dust Baler e sebelisoa haholo indastering ea temo, e entsoe ka likarolo tse tharo: hydraulic system, electronic system, main frame, e ka sebetsana le mefuta eohle ea silage e kang silage, joang ba furu, joang ba koro, haylage, Alfalfa, joang bo khaotsoeng, silage ea poone, joalo-joalo ...

1.E loketse bakeng sa mekotla ea compression ea lisebelisoa tse hlephileng

2.Output lebelo ho fihlela ho 240 lipakete / hora, phahameng bokgoni.

3.Lintho tse hatelitsoeng, tse bonolo ho li ntša, tse sebelisoang ka thepa ea mohaho oa tšireletso ea tikoloho, manyolo a masimong, temo ea li-mushroom le lisebelisoa tse ling.

Lenaneo la 4.PLC, taolo ea likonopo tsa motlakase, ts'ebetso ea ho tobetsa ha 'ngoe e phethiloe, khatello e feletseng ea sephutheloana ka nako e le' ngoe.

5.Pele ho ntša mokotla, mokotla o lokela ho behoa boema-kepe ba ho ntša ka letsoho.

6.Ho eketsoa ha taolo ea lintho tse bonahalang ho ka etsa hore mochine o qale ho hatella ka bohona, ho fepa ka letsoho kapa ho fepa ka mokhoa o itekanetseng oa conveyor e ka ba tekanyo e phahameng ea ho iketsetsa, ho boloka mosebetsi.

7.Boholo le motlakase oa block li ka etsoa ho ea ka litlhoko tse utloahalang tsa bareki, 'me boima ba block bo fapane ho ea ka thepa e fapaneng.

8.Three-phase voltage, interlock, ts'ebetso e bonolo.

9.Tšebeliso ea litiiso tse tsebahalang tsa brand master cylinder li ka ntlafatsa bophelo ba tšebeletso ea cylinder.

| Mohlala | NKB240 |

| boholo ba bale(L*W*H) | 600*400*300mm |

| Boholo ba ho bula lijo/(L*H) | 1000*600 limilimithara |

| Lisebelisoa tsa ho paka | lekgapetla la raese/ lerole la raese |

| Bokhoni ba tlhahiso | 240bale/hora |

| Bokgoni | 6-8T/hora |

| Palo ea li-volts | 200-480V/50HZ/3Phase |

| ho qhoaela | Mekotla ea polasetiki/ mekotla e lohiloeng |

| Matla | 30KW/40HP |

| Boholo ba mochini(L*W*H) | 3840*2640*2580mm |

| Mokhoa oa ho fepa | Lebanta Conveyor |

| Boima ba 'mele | 5100Kg |

Mochini oa khatiso oa pampiri ea litšila ke sekotoana sa mochini o sebelisetsoang ho khutlisetsa litšila tsa pampiri hore li be libale. Hangata e na le letoto la lirolara tse tsamaisang pampiri ka letoto la liphaposi tse futhumetseng le tse petelitsoeng, moo pampiri e kopantsoeng ka libale. Libale joale li aroloa ho litšila tse setseng tsa pampiri, tse ka sebelisoang hape kapa tsa sebelisoa hape e le lihlahisoa tse ling tsa pampiri.

Mechini ea khatiso ea pampiri ea litšila e sebelisoa hangata liindastering tse joalo ka khatiso ea likoranta, ho paka le lisebelisoa tsa ofisi. Li thusa ho fokotsa bongata ba litšila tse romelloang litsing tsa lithōle le ho khothaletsa mekhoa e tsitsitseng ka ho tsosolosa lisebelisoa tsa bohlokoa.

Mochine oa khatiso oa baling oa pampiri ea litšila ke mochini o sebelisoang litsing tsa ho tsosolosa ho kopanya le ho hatella litšila tse ngata tsa pampiri hore li be libale. Mokhoa ona o kenyelletsa ho fepa pampiri ea litšila ka har'a mochini, ebe o sebelisa lirolara ho hatella thepa le ho e etsa libale. Mechine ea khatiso ea baling e atisa ho sebelisoa libakeng tsa ho tsosolosa, 'masepala le lisebelisoa tse ling tse sebetsanang le pampiri e ngata ea litšila. Li thusa ho fokotsa bongata ba litšila tse romelloang litsing tsa lithōle le ho khothaletsa mekhoa e tsitsitseng ka ho tsosolosa lisebelisoa tsa bohlokoa

Sehlahisoa sa pampiri ea litšila ke mochini o sebelisetsoang ho kopanya le ho hatella pampiri e ngata ea litšila hore e be bale. Mokhoa ona o kenyelletsa ho fepa pampiri ea litšila ka har'a mochini, ebe o sebelisa lirolara ho hatella thepa le ho e etsa libale. Lisebelisoa tsa pampiri ea litšila li atisa ho sebelisoa libakeng tsa ho tsosolosa, limmasepala, le lisebelisoa tse ling tse sebetsanang le palo e kholo ea pampiri ea litšila. Li thusa ho fokotsa bongata ba litšila tse romelloang litsing tsa lithōle le ho khothaletsa mekhoa e tšoarellang ka ho sebelisa lisebelisoa tsa bohlokoa hape.

waste paper baling press ke mochini o sebedisoang ho kopanya le ho hatella matlakala a mangata hore e be dibale. Mokhoa ona o kenyelletsa ho fepa pampiri ea litšila ka har'a mochini, ebe o sebelisa lirolara tse futhumetseng ho hatella thepa le ho e etsa libale. Mechine ea ho hatisa pampiri e litšila e atisa ho sebelisoa libakeng tsa ho tsosolosa, 'masepala le lisebelisoa tse ling tse sebetsanang le palo e kholo ea pampiri ea litšila. Li thusa ho fokotsa bongata ba litšila tse romelloang litsing tsa lithōle le ho khothaletsa mekhoa e tsitsitseng ka ho tsosolosa lisebelisoa tsa bohlokoa.

Mochini oa khatiso oa li-waste paper baling press ke karolo ea lisebelisoa tse sebelisoang ho khutlisetsa litšila ka libaleng. Ke sesebelisoa sa bohlokoa ts'ebetsong ea ho tsosolosa, kaha e thusa ho fokotsa bongata ba litšila tse romeloang libakeng tsa ho lahlela lithōle le ho khothalletsa mekhoa e tsitsitseng ka ho tsosolosa lisebelisoa tsa bohlokoa. Sehloohong sena, re tla tšohla molao-motheo oa ts'ebetso, mefuta ea mochini oa khatiso oa pampiri ea litšila, le lits'ebetso tsa ona.

Molao-motheo o sebetsang oa mochini oa khatiso oa baling oa litšila o batla o le bonolo. Mochini o na le likarolo tse 'maloa moo pampiri ea litšila e feptjoang ho eona. Ha pampiri ea litšila e ntse e tsamaea ka har'a likarolo, e hatelloa le ho hatelloa ke li-roller tse futhumetseng, tse etsang li-bales. Libale joale li aroloa ho litšila tse setseng tsa pampiri, tse ka sebelisoang hape kapa tsa sebelisoa hape e le lihlahisoa tse ling tsa pampiri.

Mechini ea khatiso ea pampiri ea litšila e sebelisoa haholo liindastering tse kang khatiso ea likoranta, ho paka le thepa ea ofisi. Li thusa ho fokotsa bongata ba litšila tse romelloang litsing tsa lithōle le ho khothaletsa mekhoa e tsitsitseng ka ho tsosolosa lisebelisoa tsa bohlokoa. Ho feta moo, li ka boela tsa thusa ho boloka matla le ho fokotsa litšenyehelo bakeng sa likhoebo tse sebelisang lihlahisoa tsa pampiri.

E 'ngoe ea melemo ea bohlokoa ea ho sebelisa mochini oa khatiso oa pampiri ea litšila ke hore o ka thusa ho ntlafatsa boleng ba pampiri e nchafalitsoeng. Ka ho kopanya pampiri ea litšila ka libale, ho ba bonolo ho tsamaisa le ho boloka, ho fokotsa kotsi ea tšenyo le tšilafalo. Sena se nolofalletsa likhoebo ho sebelisa lipampiri tsa tsona hape le ho netefatsa hore li khona ho hlahisa lihlahisoa tsa pampiri tsa boleng bo holimo

Qetellong, mechine ea khatiso ea baling ea pampiri e litšila ke sesebelisoa sa bohlokoa ts'ebetsong ea ho tsosolosa. Li thusa ho fokotsa bongata ba litšila tse romelloang litsing tsa lithōle le ho khothaletsa mekhoa e tsitsitseng ka ho tsosolosa lisebelisoa tsa bohlokoa. Ho na le mefuta e 'meli ea mantlha ea mochini oa khatiso oa pampiri ea litšila: moea o chesang le oa mochini, 'me o sebelisoa haholo liindastering tse kang khatiso ea likoranta, ho paka le lisebelisoa tsa ofisi. Ka ho sebelisa mochini oa khatiso oa pampiri ea litšila, likhoebo li ka ntlafatsa boleng ba pampiri ea tsona e sebelisoang hape le ho fokotsa tšusumetso ea tsona tikolohong.