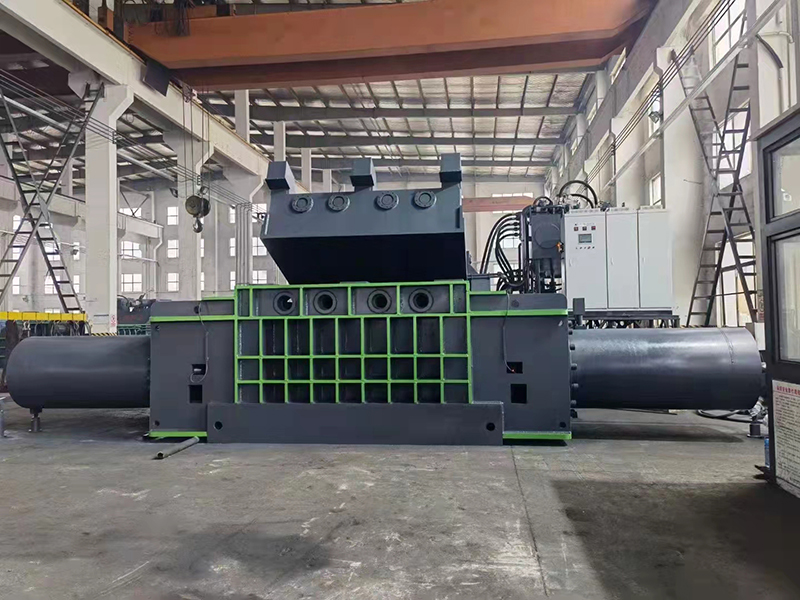

Mochini oa ho lahla Tšepe oa ho lahla

Ho sebelisoa mochini oa mohlala oa ho beola tšepe ea lithōle, o ka sebelisoang ho sebetsana le mefuta eohle ea tšepe ea lithōle hore e be khutlonnetsepa, octagon, le seleine, ho etsa hore lithōle tsena li tšoanelehe bakeng sa litlhoko tsa ho qhibiliha ha sebōpi, ho boloka litšenyehelo tsa lipalangoang le ho qhibiliha, ho eketsa lebelo la ho qhibiliha le sekhahla. Ho ntša lithōle tse fapaneng tsa tšepe (li-cut, li-shavings, tšepe ea lithōle, aluminium ea lithōle, koporo ea lithōle, tšepe ea lithōle, tšepe e sa hloekang, jj.) ka botenya ba ka tlase ho 6 mm ka har'a libopeho tse fapaneng tsa thepa e tšoanelehang joalo ka li-cube, li-cylinder le li-octagon. E 'ngoe e sebelisoa ho lahla litsi tsa ts'ebetso le kabo (li-base), lik'hamphani tse qhaqhollang likoloi le ho etsa bocha, liindasteri tsa tšepe le tse se nang tšepe. Ho hatella tšepe e senyehileng mehloling ea tšepe e boholo ba edium kapa e kholo, li-briquette tsena tsa tšepe li bonolo ho li tsamaisa le ho li boloka ka har'a lithōle hammoho le ho boloka mobu o mongata. Libopeho tsa ho qetela tse kang li-cube, li-cylinder, li-octagons, jj. Ha e le thepa ena e senyehileng e tsoa haholo lifemeng tse sebelisang hape le lifemeng tsa tlhahiso ea lihlahisoa tsa tšepe, ho qhaqha likoloi, fektheri ea tšepe, ho beola tšepe, koporo, rebar, tšepe e senyehileng, aluminium e senyehileng, li-mill tsa tšepe, liindasteri tsa ho sebelisa hape le ho sebetsana le tsona, liindasteri tsa ho qhibilihisa tšepe tse se nang tšepe le tsa ferrous, esita le ho kenyeletsoa le li-yard tsa lithōle, li-rolling mills, li-oven le li-unit tse qhibilihisang le li-unit tse kholo tsa tlhahiso tse hlahisang lithōle tsa tšepe. Lithaele tsa tšepe tse mebala-bala, maqephe a tšepe a bobebe le a masesaane, li-block tsa tšepe tsa kolobe, makotikoti, makotikoti a biri, li-flakes tsa aluminium tse senyehileng, li-block tsa koporo tse senyehileng, libarele tsa tšepe, likhetla tsa likoloi, li-rack tsa likoloi le thepa ea alloy ea aluminium.

1. Sistimi e tsitsitseng le e sebetsang hantle ea ho khanna ea hydraulic, mohele oa letsoho kapa ts'ebetso e felletseng ea othomathiki ea PLC e ikhethelang

2. mekhoa e fapaneng ea ho ntša bale ka boikhethelo, ho reteleha, ho sutumelletsa lehlakore kantle, ho sutumelletsa ka pele kantle, ho ntša ka letsoho jj.

3. mehlala e fapaneng bakeng sa litlhoko tse ikhethileng: mabotho a fapaneng a khatiso, boholo ba mabokose, libopeho tsa bale

4. Matla a motlakase le a enjene ea diesel aa fumaneha

5. Liparamente tsa tekheniki tse kaholimo ha li tlame, re ipoloka tokelo ea ho fetola ho latela tlhoko ea 'nete.

6. Haeba o hloka mehlala e seng ya maemo a hodimo e nang le boholo bo fapaneng ba lebokose la kgatiso, boholo bo fapaneng ba bale, o ka re letsetsa kapa wa re romela imeile bakeng sa ho iketsetsa.

7. E tsamaisoa ke motlakase ka ts'ebetso ea letsoho kapa taolo ea othomathiki ea PLC.

8. Ho ntsha bale: "ho ntsha" , "ho sutumelletsa kantle", "ho ntsha ka pele" le ho ntsha ka letsoho.

9. Ho kenya lisebelisoa ntle le tlhoko ea li-bolt tsa ankora bakeng sa tlhahiso e bonolo kapa tokiso ea sebopeho sa lisebelisoa

10. E ka hlomelloa ka enjene ea disele e le phepelo ea motlakase ea bekapo

11. Ha o tobetsa ho tloha mahlakoreng a mararo, dibale tse hatelletsoeng di tla ba le bongata bo phahameng

12.Ts'ebetso e bonolo, e sebetsang hantle ebile e bolokehile

| Mofuta | Matla a Ikhethang (KN) | Matla (Kw) | Boholo ba Lebokose la Phepo (mm) | Boholo ba Bale (mm) | Tlhahiso (Kg/h) | Ts'ebetso |

| NKY81-4000A | 4000 | 66 | 2600*1600*1200 | 550*550 | 4000-7000 | Ka letsoho / PLC |

| NKY81-4000B | 4000 | 110 | 2000*1600*1100 | 550*500 | 4000-7000 | Ka letsoho / PLC |

| NKY81-6000 | 6000 | 135 | 5000*2000*1200 | 700*700 | 8000-10000 | Ka letsoho / PLC |

Mochini oa khatiso oa ho lokisa pampiri ea litšila ke mochini o sebelisetsoang ho sebelisa hape litšila tsa pampiri hore e be li-bale. Hangata o na le letoto la li-roller tse tsamaisang pampiri ka har'a letoto la likamore tse futhumetseng le tse hatelitsoeng, moo pampiri e kopanngoang hore e be li-bale. Ebe li-bale li aroloa ho litšila tsa pampiri tse setseng, tse ka sebelisoang hape kapa tsa sebelisoa hape e le lihlahisoa tse ling tsa pampiri.

Mechini ea khatiso ea ho qhaqha lipampiri tsa litšila e sebelisoa haholo indastering e kang khatiso ea likoranta, liphutheloana le thepa ea ofisi. E thusa ho fokotsa bongata ba litšila tse romeloang libakeng tsa ho lahla lithōle le ho khothalletsa mekhoa e tsitsitseng ka ho sebelisa mehloli ea bohlokoa hape.

Mochini o hatisang lipampiri tse senyehileng ke mochini o sebelisoang litsing tsa ho sebelisa hape ho kopanya le ho hatella litšila tse ngata tsa pampiri hore li be li-bale. Ts'ebetso ena e kenyelletsa ho fepa pampiri e senyehileng ka har'a mochini, ebe o sebelisa li-roller ho hatella thepa le ho e etsa li-bale. Li-baling press li sebelisoa hangata litsing tsa ho sebelisa hape, metseng ea masepala le litsing tse ling tse sebetsanang le boholo bo boholo ba pampiri e senyehileng. Li thusa ho fokotsa bongata ba litšila tse romelloang libakeng tsa ho lahla lithōle le ho khothaletsa mekhoa e tsitsitseng ka ho sebelisa hape lisebelisoa tsa bohlokoa.

Mochini o sebelisang pampiri ea litšila ke mochini o sebelisetsoang ho kopanya le ho hatella pampiri e ngata ea litšila hore e be li-bale. Ts'ebetso ena e kenyelletsa ho kenya pampiri ea litšila ka har'a mochini, ebe o sebelisa li-roller ho hatella thepa le ho e etsa li-bale. Li-bale tsa pampiri ea litšila li sebelisoa hangata litsing tsa ho sebelisa lintho hape, metseng ea masepala le litsing tse ling tse sebetsanang le boholo bo boholo ba pampiri ea litšila. Li thusa ho fokotsa bongata ba litšila tse romeloang libakeng tsa ho lahla lithōle le ho khothaletsa mekhoa e tsitsitseng ka ho sebelisa lisebelisoa tsa bohlokoa hape. joalo ka ha u fumana leseli le eketsehileng, ka kopo re etele: https://www.nkbaler.com/

Mochini oa ho beola pampiri ea litšila ke mochini o sebelisetsoang ho kopanya le ho hatella palo e kholo ea pampiri ea litšila hore e be li-bale. Ts'ebetso ena e kenyelletsa ho fepa pampiri ea litšila ka har'a mochini, ebe o sebelisa li-roller tse futhumetseng ho hatella thepa le ho e etsa li-bale. Mechini ea ho beola pampiri ea litšila e sebelisoa hangata litsing tsa ho sebelisa lintho hape, metseng ea masepala le litsing tse ling tse sebetsanang le boholo bo boholo ba pampiri ea litšila. Li thusa ho fokotsa palo ea litšila tse romelloang libakeng tsa ho lahla lithōle le ho khothaletsa mekhoa e tsitsitseng ka ho sebelisa hape mehloli ea bohlokoa.

Mochini oa khatiso oa ho lokisa pampiri ea litšila ke sesebelisoa se sebelisetsoang ho sebelisa pampiri ea litšila hape hore e be li-bale. Ke sesebelisoa sa bohlokoa ts'ebetsong ea ho sebelisa hape, kaha se thusa ho fokotsa bongata ba litšila tse romeloang libakeng tsa ho lahla lithōle le ho khothaletsa mekhoa e tsitsitseng ka ho sebelisa hape mehloli ea bohlokoa. Sehloohong sena, re tla buisana ka molao-motheo oa ts'ebetso, mefuta ea mechini ea khatiso ea ho lokisa pampiri ea litšila, le ts'ebeliso ea eona.

Molao-motheo o sebetsang oa mochini oa khatiso oa ho lokisa pampiri e litšila o bonolo haholo. Mochini o na le likarolo tse 'maloa moo pampiri e litšila e fepuoang teng. Ha pampiri e litšila e ntse e tsamaea ka har'a likarolo, e petsoha le ho hatelloa ke lirolara tse futhumetseng, tse etsang li-bale. Li-bale li aroloa ho litšila tsa pampiri tse setseng, tse ka sebelisoang hape kapa tsa sebelisoa hape e le lihlahisoa tse ling tsa pampiri.

Mechini ea khatiso ea ho qhaqha lipampiri tsa litšila e sebelisoa haholo liindastering tse kang khatiso ea likoranta, liphutheloana le thepa ea ofisi. E thusa ho fokotsa bongata ba litšila tse romeloang libakeng tsa ho lahla lithōle le ho khothalletsa mekhoa e tsitsitseng ka ho sebelisa mehloli ea bohlokoa hape. Ho phaella moo, e ka boela ea thusa ho boloka matla le ho fokotsa litšenyehelo bakeng sa likhoebo tse sebelisang lihlahisoa tsa pampiri.

E 'ngoe ea melemo ea bohlokoa ea ho sebelisa mochini oa khatiso oa ho lokisa pampiri e senyehileng ke hore e ka thusa ho ntlafatsa boleng ba pampiri e sebelisitsoeng hape. Ka ho kopanya pampiri e senyehileng hore e be li-bale, ho ba bonolo ho e tsamaisa le ho e boloka, ho fokotsa kotsi ea tšenyo le tšilafalo. Sena se nolofalletsa likhoebo ho sebelisa pampiri ea tsona e senyehileng hape le ho netefatsa hore li khona ho hlahisa lihlahisoa tsa pampiri tsa boleng bo holimo.

Qetellong, mechine ea khatiso ea ho lokisa pampiri e senyehileng ke sesebelisoa sa bohlokoa ts'ebetsong ea ho sebelisa hape. E thusa ho fokotsa bongata ba litšila tse romelloang libakeng tsa ho lahla lithōle le ho khothalletsa mekhoa e tsitsitseng ka ho sebelisa hape mehloli ea bohlokoa. Ho na le mefuta e 'meli e meholo ea mechine ea khatiso ea ho lokisa pampiri e senyehileng: ea moea o chesang le ea mechine, 'me e sebelisoa haholo liindastering tse kang khatiso ea likoranta, liphutheloana le thepa ea ofisi. Ka ho sebelisa mochini oa khatiso oa ho lokisa pampiri e senyehileng, likhoebo li ka ntlafatsa boleng ba pampiri ea tsona e sebelisitsoeng hape le ho fokotsa tšusumetso ea tsona tikolohong.