Mochini oa ho paka pampiri oa Occ

Mochini oa ho Paka Lipampiri oa NKW80BD Occ ke sesebelisoa sa compression sa khateboto e sebetsang hantle haholo ebile e se nang tikoloho. E sebelisa theknoloji e tsoetseng pele ea hydraulic ho hatella khateboto hore e be li-block blocks bakeng sa lipalangoang le kalafo e bonolo. Mochini o na le melemo ea ts'ebetso e bonolo, tlhokomelo e bonolo, le tšebeliso e tlase ea matla, 'me e sebelisoa haholo indastering ea tlhahiso ea li-cardboard.

Mosebetsi o ka sehloohong oa NKW80BD Occ Packing Machine ke ho hatella khateboto hore e be li-block blocks ho tsamaisa lipalangoang le ho sebetsa. Ka ho sebelisa mochini ona, likhoebo li ka fokotsa litšenyehelo tsa lipalangoang, tsa eketsa tšebeliso ea khateboto hape, le ho kenya letsoho ts'ireletsong ea tikoloho. Ho phaella moo, mochine o boetse o loketse ho hatella lisebelisoa tse ling, tse kang polasetiki ea litšila, lebokose, joalo-joalo, e nang le mekhoa e mengata e fapaneng.

Litšobotsi tsa Mochini oa Packing oa NKW80BD Occ ke tse latelang:

1. Khatello e phahameng ea katleho: Ka tsamaiso ea hydraulic, polasetiki ea litšila e hatelloa ka har'a boima bo kopanetsoeng, e leng ho ntlafatsang haholo bokhoni ba lipalangoang le polokelo.

2. Ho boloka matla le ho sireletsa tikoloho: Tšebeliso e ncha ea litšila tsa polasetiki e sentsoeng e fokolitse tšilafalo ea tikoloho 'me e lumellana le khopolo ea tsoelo-pele e tsitsitseng.

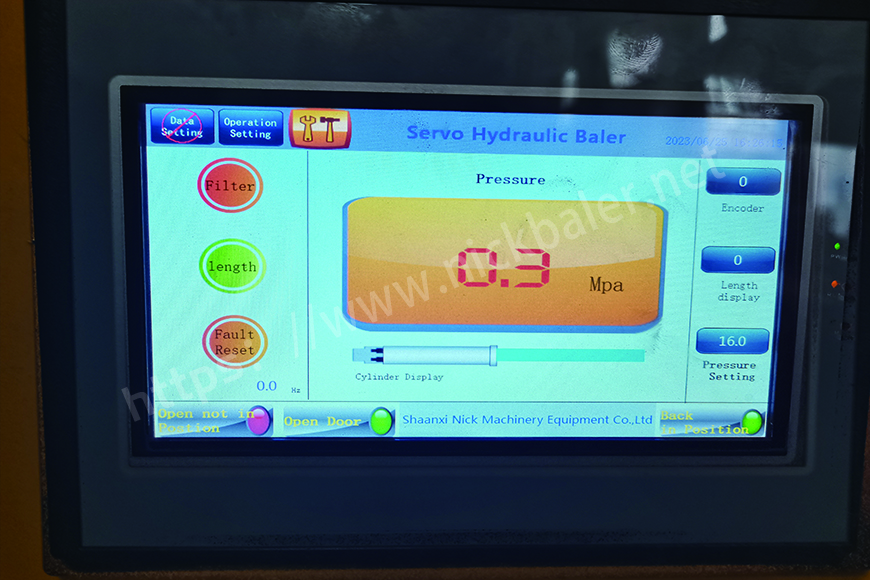

3. Ts'ebetso e bonolo: Tekanyo e phahameng ea boiketsetso, tobetsa konopo feela ho phethela ts'ebetso eohle ea ho hatella, ho boloka litšenyehelo tsa basebetsi.

4. Tlhokomelo e bonolo: sebopeho se bonolo, tlhokomelo e bonolo le tlhokomelo, ho fokotsa sekhahla sa ho hlōleha ha thepa.

5. Tšireletseho le ho tšepahala: ho na le sesebelisoa sa tšireletso se sireletsang ho netefatsa polokeho ea opareitara.

| Mohlala | NKW80BD |

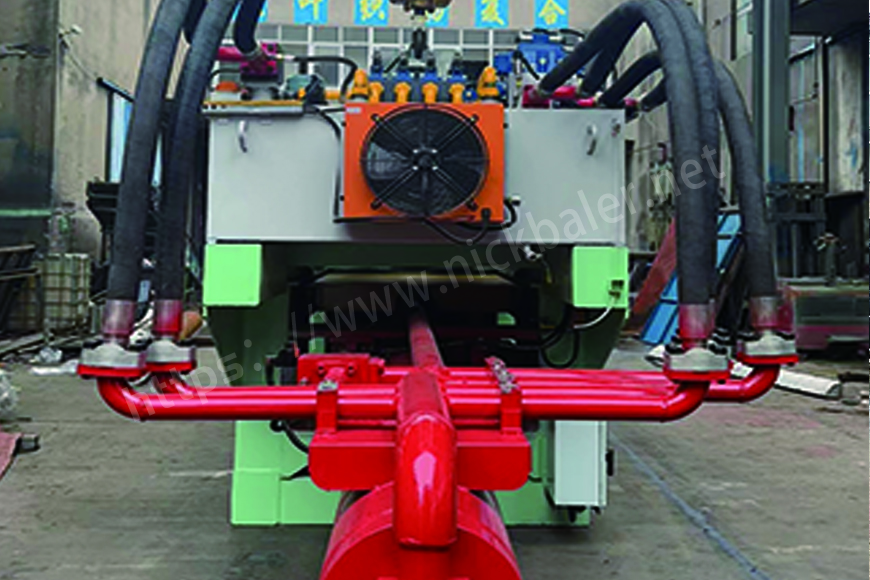

| Matla a hydraulic | 80Ton |

| Boholo ba silinda | Ø200 |

| Baleboholo(W*H*L) | 1000*800*300-1700 limilimithara |

| Fepa boholo ba ho bula(L*W) | 1200*1000 limilimithara |

| Bale density | 350-450Kg/m3 |

| Bokgoni | 2-3T/hora |

| Bale line | 5Mola (mo-la-na) /Manual strapping |

| Matla | 22KW/30HP |

| Out-bale tsela | Mokotla o lahliloeng o tsoa |

| Bale-terata | 10#*4 li-PC |

| Sistimi ea ho pholisa | Fan e phodileng |

| Sesebelisoa sa ho fepa | morekisi |

| Boima ba mochini | 12500KG |

| Conveyor | 12000mm*1800mm(L*W) 4.5KW |

| Conveyorboima | 4500kg |

| Sistimi ea ho pholisa | Water cooling |

Mochini oa khatiso oa pampiri ea litšila ke sekotoana sa mochini o sebelisetsoang ho khutlisetsa litšila tsa pampiri hore li be libale. Hangata e na le letoto la lirolara tse tsamaisang pampiri ka letoto la liphaposi tse futhumetseng le tse petelitsoeng, moo pampiri e kopantsoeng ka libale. Libale joale li aroloa ho litšila tse setseng tsa pampiri, tse ka sebelisoang hape kapa tsa sebelisoa hape e le lihlahisoa tse ling tsa pampiri.

Mechini ea khatiso ea pampiri ea litšila e sebelisoa hangata liindastering tse joalo ka khatiso ea likoranta, ho paka le lisebelisoa tsa ofisi. Li thusa ho fokotsa bongata ba litšila tse romelloang litsing tsa lithōle le ho khothaletsa mekhoa e tsitsitseng ka ho tsosolosa lisebelisoa tsa bohlokoa.

Mochine oa khatiso oa baling oa pampiri ea litšila ke mochini o sebelisoang litsing tsa ho tsosolosa ho kopanya le ho hatella litšila tse ngata tsa pampiri hore li be libale. Mokhoa ona o kenyelletsa ho fepa pampiri ea litšila ka har'a mochini, ebe o sebelisa lirolara ho hatella thepa le ho e etsa libale. Mechine ea khatiso ea baling e atisa ho sebelisoa libakeng tsa ho tsosolosa, 'masepala le lisebelisoa tse ling tse sebetsanang le pampiri e ngata ea litšila. Li thusa ho fokotsa bongata ba litšila tse romelloang litsing tsa lithōle le ho khothaletsa mekhoa e tsitsitseng ka ho tsosolosa lisebelisoa tsa bohlokoa

Sehlahisoa sa pampiri ea litšila ke mochini o sebelisetsoang ho kopanya le ho hatella pampiri e ngata ea litšila hore e be bale. Mokhoa ona o kenyelletsa ho fepa pampiri ea litšila ka har'a mochini, ebe o sebelisa lirolara ho hatella thepa le ho e etsa libale. Lisebelisoa tsa pampiri ea litšila li atisa ho sebelisoa libakeng tsa ho tsosolosa, limmasepala, le lisebelisoa tse ling tse sebetsanang le palo e kholo ea pampiri ea litšila. Li thusa ho fokotsa bongata ba litšila tse romelloang litsing tsa lithōle le ho khothaletsa mekhoa e tšoarellang ka ho sebelisa lisebelisoa tsa bohlokoa hape.

waste paper baling press ke mochini o sebedisoang ho kopanya le ho hatella matlakala a mangata hore e be dibale. Mokhoa ona o kenyelletsa ho fepa pampiri ea litšila ka har'a mochini, ebe o sebelisa lirolara tse futhumetseng ho hatella thepa le ho e etsa libale. Mechine ea ho hatisa pampiri e litšila e atisa ho sebelisoa libakeng tsa ho tsosolosa, 'masepala le lisebelisoa tse ling tse sebetsanang le palo e kholo ea pampiri ea litšila. Li thusa ho fokotsa bongata ba litšila tse romelloang litsing tsa lithōle le ho khothaletsa mekhoa e tsitsitseng ka ho tsosolosa lisebelisoa tsa bohlokoa.

Mochini oa khatiso oa li-waste paper baling press ke karolo ea lisebelisoa tse sebelisoang ho khutlisetsa litšila ka libaleng. Ke sesebelisoa sa bohlokoa ts'ebetsong ea ho tsosolosa, kaha e thusa ho fokotsa bongata ba litšila tse romeloang libakeng tsa ho lahlela lithōle le ho khothalletsa mekhoa e tsitsitseng ka ho tsosolosa lisebelisoa tsa bohlokoa. Sehloohong sena, re tla tšohla molao-motheo oa ts'ebetso, mefuta ea mochini oa khatiso oa pampiri ea litšila, le lits'ebetso tsa ona.

Molao-motheo o sebetsang oa mochini oa khatiso oa baling oa litšila o batla o le bonolo. Mochini o na le likarolo tse 'maloa moo pampiri ea litšila e feptjoang ho eona. Ha pampiri ea litšila e ntse e tsamaea ka har'a likarolo, e hatelloa le ho hatelloa ke li-roller tse futhumetseng, tse etsang li-bales. Libale joale li aroloa ho litšila tse setseng tsa pampiri, tse ka sebelisoang hape kapa tsa sebelisoa hape e le lihlahisoa tse ling tsa pampiri.

Mechini ea khatiso ea pampiri ea litšila e sebelisoa haholo liindastering tse kang khatiso ea likoranta, ho paka le thepa ea ofisi. Li thusa ho fokotsa bongata ba litšila tse romelloang litsing tsa lithōle le ho khothaletsa mekhoa e tsitsitseng ka ho tsosolosa lisebelisoa tsa bohlokoa. Ho feta moo, li ka boela tsa thusa ho boloka matla le ho fokotsa litšenyehelo bakeng sa likhoebo tse sebelisang lihlahisoa tsa pampiri.

E 'ngoe ea melemo ea bohlokoa ea ho sebelisa mochini oa khatiso oa pampiri ea litšila ke hore o ka thusa ho ntlafatsa boleng ba pampiri e nchafalitsoeng. Ka ho kopanya pampiri ea litšila ka libale, ho ba bonolo ho tsamaisa le ho boloka, ho fokotsa kotsi ea tšenyo le tšilafalo. Sena se nolofalletsa likhoebo ho sebelisa lipampiri tsa tsona hape le ho netefatsa hore li khona ho hlahisa lihlahisoa tsa pampiri tsa boleng bo holimo

Qetellong, mechine ea khatiso ea baling ea pampiri e litšila ke sesebelisoa sa bohlokoa ts'ebetsong ea ho tsosolosa. Li thusa ho fokotsa bongata ba litšila tse romelloang litsing tsa lithōle le ho khothaletsa mekhoa e tsitsitseng ka ho tsosolosa lisebelisoa tsa bohlokoa. Ho na le mefuta e 'meli ea mantlha ea mochini oa khatiso oa pampiri ea litšila: moea o chesang le oa mochini, 'me o sebelisoa haholo liindastering tse kang khatiso ea likoranta, ho paka le lisebelisoa tsa ofisi. Ka ho sebelisa mochini oa khatiso oa pampiri ea litšila, likhoebo li ka ntlafatsa boleng ba pampiri ea tsona e sebelisoang hape le ho fokotsa tšusumetso ea tsona tikolohong.