Mochini oa ho Hatisa oa ho Jala ka Bophara

Sesebediswa sa ho qhaqha dipampiri tsa matlakala ka boiketsetso ke tshebetso e sa etswang ke motho ka ho feletseng mme se loketse dibaka tse nang le thepa e ngata. Kamora hore dintho di hatellwe le ho kopanngwa, ho bonolo ho di boloka le ho di paka le ho fokotsa ditjeo tsa dipalangwang. Sesebediswa se ikgethang sa ho qhaqha dipampiri tsa matlakala ka boiketsetso sa sesebediswa sa ho qhaqha dipampiri tsa matlakala ka boiketsetso se potlakile, se bonolo ka sebopeho, se tsitsitse tshebetsong, se na le sekgahla se tlase sa ho hloleha mme se bonolo ho se hlokomela. Sesebediswa sa ho qhaqha dipampiri tsa matlakala ka boiketsetso se loketse mabokose a dipampiri tsa matlakala, dipolasetiki, masela le dibaka tse kgolo tsa ho lahla dithōle.

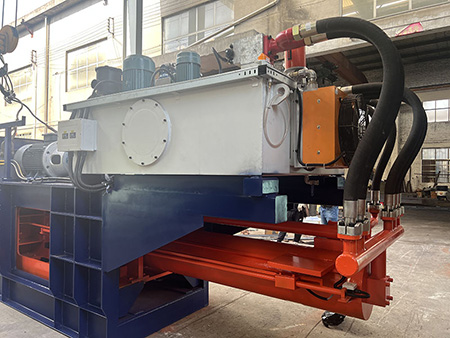

Mohala oa tlhahiso ea baler ea pampiri ea litšila o iketsang o entsoe ka mochini o ka sehloohong, conveyor, hopper, le sistimi ea ho pholisa moea. Baler ea pampiri ea litšila o iketsang o na le ts'ebetso e tsitsitseng, ts'ebetso e theko e phahameng, ts'ebetso e bonolo le ts'ebetso e ntle ea polokeho. E loketse Baler mefuta eohle ea karete ea litšila,

mabokose a pampiri ea litšila, likhetla tsa pampiri ea litšila, libarele tsa pampiri ea litšila, mathōko a pampiri ea litšila, polasetiki ea litšila, le lithōle tse ling tsa litšila ho li etsa liboloko ho finyella ho boloka litšenyehelo le ho tsamaisoa habonolo.

1. Mefuta eohle ea NICKBALER e tsamaisoa ka metsi.

2. Ts'ebetso e sa etswang ke motho ka boiketsetso ka botlalo, ho hatisa le ho ntsha dibolo ka boiketsetso, bokgoni bo phahameng ba mosebetsi

3. Phetolelo e felletseng ea Senyesemane ea sebopeho sa ts'ebetso e u lumella ho bona hang-hang

4. Amohela taolo ea sistimi ea servo, theknoloji e tsoetseng pele le ts'ebetso e bonolo

5. Lebokose la enjene le behiloe ka tsela e utloahalang le e ntle

6. E na le litaelo tse qaqileng tsa ts'ebetso le matšoao a totobetseng a tšireletso

7. Lisebelisoa li tsitsitse 'me ha ho hlokahale li-screw tsa maoto bakeng sa ho kenya

| Ntho | Lebitso | paramethara |

| foreimi e ka sehloohong paramethara | Boholo ba bale | 1100mm()W)×1100mm()H)×~1800mm(L) |

| Mofuta oa thepa | Pampiri ea Kraft e senyehileng, Koranta, Khateboto, Filimi e Bonolo, Plastiki, | |

| Botenya ba thepa | 650~750Kg/m3()Mongobo 12-18%) | |

| Boholo ba ho bula ha fepe | 2400mm × 1100mm | |

| Matla a maholo a enjene | 37KW×2lisete+15KW | |

| Silindara e kholo | YG300/230-2900 | |

| Matla a mantlha a silindara | 200T | |

| Bokgoni | 28-30Ton/hora | |

| Matla a maholo a sebetsang a sistimi | 30.5MPa | |

| Boima ba foreimi e kholo (T) | Lithane tse ka bang 30 | |

| Tanka ea oli | 2m3 | |

| Boholo ba foreimi e kholo | Hoo e ka bang 11×4.3×5.8M()L×W×H) | |

| Thae terata ea terata | 4mola φ3.0-3.2mm3 terata ea tšepe | |

| Nako ea khatello | ≤30S/ (eya le ho kgutla bakeng sa mojaro o se nang letho) | |

| Theknoloji ea ho tsamaisa ketane | Mohlala | NK-III |

| Boima ba conveyor | Mabapi le7lithane | |

| Boholo ba conveyor | 2000*14000MM | |

| boholo ba lesoba la terra | 7.303M()L)×3.3M()W)×1.2M()tebileng) | |

| Enjene ea conveyor | 7.5KW | |

| Tora e pholileng | Enjene e pholileng ea tora | 0.75KW()Pompo ea metsi)+0.25()Fene) |

Mochini oa khatiso oa ho lokisa pampiri ea litšila ke mochini o sebelisetsoang ho sebelisa hape litšila tsa pampiri hore e be li-bale. Hangata o na le letoto la li-roller tse tsamaisang pampiri ka har'a letoto la likamore tse futhumetseng le tse hatelitsoeng, moo pampiri e kopanngoang hore e be li-bale. Ebe li-bale li aroloa ho litšila tsa pampiri tse setseng, tse ka sebelisoang hape kapa tsa sebelisoa hape e le lihlahisoa tse ling tsa pampiri.

Mechini ea khatiso ea ho qhaqha lipampiri tsa litšila e sebelisoa haholo indastering e kang khatiso ea likoranta, liphutheloana le thepa ea ofisi. E thusa ho fokotsa bongata ba litšila tse romeloang libakeng tsa ho lahla lithōle le ho khothalletsa mekhoa e tsitsitseng ka ho sebelisa mehloli ea bohlokoa hape.

Mochini o hatisang lipampiri tse senyehileng ke mochini o sebelisoang litsing tsa ho sebelisa hape ho kopanya le ho hatella litšila tse ngata tsa pampiri hore li be li-bale. Ts'ebetso ena e kenyelletsa ho fepa pampiri e senyehileng ka har'a mochini, ebe o sebelisa li-roller ho hatella thepa le ho e etsa li-bale. Li-baling press li sebelisoa hangata litsing tsa ho sebelisa hape, metseng ea masepala le litsing tse ling tse sebetsanang le boholo bo boholo ba pampiri e senyehileng. Li thusa ho fokotsa bongata ba litšila tse romelloang libakeng tsa ho lahla lithōle le ho khothaletsa mekhoa e tsitsitseng ka ho sebelisa hape lisebelisoa tsa bohlokoa.

Mochini o sebelisang pampiri ea litšila ke mochini o sebelisetsoang ho kopanya le ho hatella pampiri e ngata ea litšila hore e be li-bale. Ts'ebetso ena e kenyelletsa ho kenya pampiri ea litšila ka har'a mochini, ebe o sebelisa li-roller ho hatella thepa le ho e etsa li-bale. Li-bale tsa pampiri ea litšila li sebelisoa hangata litsing tsa ho sebelisa lintho hape, metseng ea masepala le litsing tse ling tse sebetsanang le boholo bo boholo ba pampiri ea litšila. Li thusa ho fokotsa bongata ba litšila tse romeloang libakeng tsa ho lahla lithōle le ho khothaletsa mekhoa e tsitsitseng ka ho sebelisa lisebelisoa tsa bohlokoa hape. joalo ka ha u fumana leseli le eketsehileng, ka kopo re etele: https://www.nkbaler.com/

Mochini oa ho beola pampiri ea litšila ke mochini o sebelisetsoang ho kopanya le ho hatella palo e kholo ea pampiri ea litšila hore e be li-bale. Ts'ebetso ena e kenyelletsa ho fepa pampiri ea litšila ka har'a mochini, ebe o sebelisa li-roller tse futhumetseng ho hatella thepa le ho e etsa li-bale. Mechini ea ho beola pampiri ea litšila e sebelisoa hangata litsing tsa ho sebelisa lintho hape, metseng ea masepala le litsing tse ling tse sebetsanang le boholo bo boholo ba pampiri ea litšila. Li thusa ho fokotsa palo ea litšila tse romelloang libakeng tsa ho lahla lithōle le ho khothaletsa mekhoa e tsitsitseng ka ho sebelisa hape mehloli ea bohlokoa.

Mochini oa khatiso oa ho lokisa pampiri ea litšila ke sesebelisoa se sebelisetsoang ho sebelisa pampiri ea litšila hape hore e be li-bale. Ke sesebelisoa sa bohlokoa ts'ebetsong ea ho sebelisa hape, kaha se thusa ho fokotsa bongata ba litšila tse romeloang libakeng tsa ho lahla lithōle le ho khothaletsa mekhoa e tsitsitseng ka ho sebelisa hape mehloli ea bohlokoa. Sehloohong sena, re tla buisana ka molao-motheo oa ts'ebetso, mefuta ea mechini ea khatiso ea ho lokisa pampiri ea litšila, le ts'ebeliso ea eona.

Molao-motheo o sebetsang oa mochini oa khatiso oa ho lokisa pampiri e litšila o bonolo haholo. Mochini o na le likarolo tse 'maloa moo pampiri e litšila e fepuoang teng. Ha pampiri e litšila e ntse e tsamaea ka har'a likarolo, e petsoha le ho hatelloa ke lirolara tse futhumetseng, tse etsang li-bale. Li-bale li aroloa ho litšila tsa pampiri tse setseng, tse ka sebelisoang hape kapa tsa sebelisoa hape e le lihlahisoa tse ling tsa pampiri.

Mechini ea khatiso ea ho qhaqha lipampiri tsa litšila e sebelisoa haholo liindastering tse kang khatiso ea likoranta, liphutheloana le thepa ea ofisi. E thusa ho fokotsa bongata ba litšila tse romeloang libakeng tsa ho lahla lithōle le ho khothalletsa mekhoa e tsitsitseng ka ho sebelisa mehloli ea bohlokoa hape. Ho phaella moo, e ka boela ea thusa ho boloka matla le ho fokotsa litšenyehelo bakeng sa likhoebo tse sebelisang lihlahisoa tsa pampiri.

E 'ngoe ea melemo ea bohlokoa ea ho sebelisa mochini oa khatiso oa ho lokisa pampiri e senyehileng ke hore e ka thusa ho ntlafatsa boleng ba pampiri e sebelisitsoeng hape. Ka ho kopanya pampiri e senyehileng hore e be li-bale, ho ba bonolo ho e tsamaisa le ho e boloka, ho fokotsa kotsi ea tšenyo le tšilafalo. Sena se nolofalletsa likhoebo ho sebelisa pampiri ea tsona e senyehileng hape le ho netefatsa hore li khona ho hlahisa lihlahisoa tsa pampiri tsa boleng bo holimo.

Qetellong, mechine ea khatiso ea ho lokisa pampiri e senyehileng ke sesebelisoa sa bohlokoa ts'ebetsong ea ho sebelisa hape. E thusa ho fokotsa bongata ba litšila tse romelloang libakeng tsa ho lahla lithōle le ho khothalletsa mekhoa e tsitsitseng ka ho sebelisa hape mehloli ea bohlokoa. Ho na le mefuta e 'meli e meholo ea mechine ea khatiso ea ho lokisa pampiri e senyehileng: ea moea o chesang le ea mechine, 'me e sebelisoa haholo liindastering tse kang khatiso ea likoranta, liphutheloana le thepa ea ofisi. Ka ho sebelisa mochini oa khatiso oa ho lokisa pampiri e senyehileng, likhoebo li ka ntlafatsa boleng ba pampiri ea tsona e sebelisitsoeng hape le ho fokotsa tšusumetso ea tsona tikolohong.