Alfalfal Hay Baling Machine

NKBD160BD Alfalfal Hay Baling Machine e sebelisoa bakeng sa ho kopanya le ho paka lesere la hay

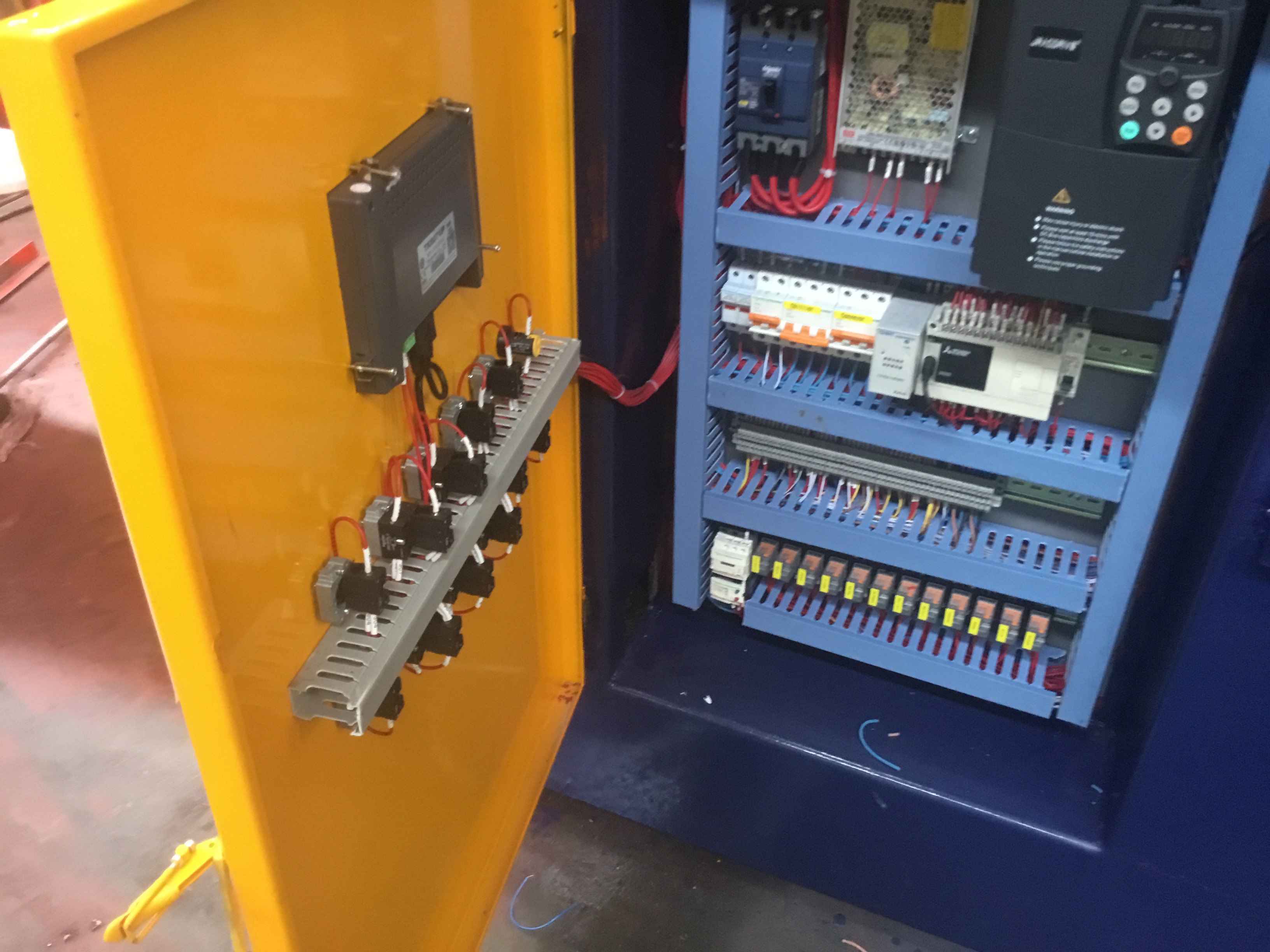

Nick Machinery ke morekisi oa litsebi oa alfa alfa baler naheng ea China ka lilemo tse mashome. Likarolo tsohle tsa li-balers tsa rona li nka mofuta o holimo, joalo ka tšepe ea sebopeho sa mochini oa mochini o sebelisang mofuta oa Bao Steel naheng ea China. Bakeng sa lisebelisoa tsa motlakase, re sebelisa mofuta o motle ka ho fetisisa joalo ka Siemens, Schneider joalo-joalo 'me hape re ka sustomize ho latela litlhoko tsa bareki ba rona, rea u amohela ho ikopanya le rona ho fumana komporo ea hau e loketseng ka ho fetisisa ea alfa alfa baling.

1. Sebopeho se otlolohileng se nang le lebanta la conveyor bakeng sa ho fepa ho boloka nako le mosebetsi.

2. Ho tšepahala ka ts'ebetso ea konopo le taolo ea PLC

3. Mofuta oa lipoleiti tsa ketane kapa mofuta oa lebanta la conveyor e ka ba khetho e nang le matla a maholo a ho tsamaisa, ho hanyetsa ho roala, matla a matla a mojaro le mosebetsi o khahlanong le ho thella;

4. Bolelele ba ho paka bo ka behoa ka bolokolohi, 'me microcomputer e ka ngola ka nepo boleng ba ho paka le katleho ea tlhahiso.

5. Tšebeliso e tlaase ea matla, maoto a manyenyane, boima bo phahameng, tlhahiso e phahameng, motsamao o bonolo, ts'ebetso e bonolo le ho tšepahala;

6.The baler e na le sebopeho se makhethe le sekhahla se phahameng, se fokotsang sebaka sa lipalangoang le sa polokelo 'me se fokotsa haholo litšenyehelo tsa lipalangoang le tsa polokelo. Ke sesebelisoa se loketseng sa ho paka bakeng sa bareki ba baholo, ba mahareng le ba banyenyane.

| Mohlala | NKW160BD |

| Matla a hydraulic | 160Ton |

| Boholo ba silinda | Ø280 |

| Baleboholo(W*H*L) | 1100*1250*1700mm |

| Fepa boholo ba ho bula(L*W) | 2000*1100 limilimithara |

| Bale density | 600-650Kg/m3 |

| Bokgoni | 6-8T/hora |

| Bale line | 7Mola (mo-la) /Manual strapping |

| Matla/ | 37.5KW/50HP |

| Out-bale tsela | Mokotla o lahliloeng o tsoa |

| Bale-terata | 6#/8#*7 li-PC |

| Boima ba mochini | 19000KG |

Mochini oa khatiso oa pampiri ea litšila ke sekotoana sa mochini o sebelisetsoang ho khutlisetsa litšila tsa pampiri hore li be libale. Hangata e na le letoto la lirolara tse tsamaisang pampiri ka letoto la liphaposi tse futhumetseng le tse petelitsoeng, moo pampiri e kopantsoeng ka libale. Libale joale li aroloa ho litšila tse setseng tsa pampiri, tse ka sebelisoang hape kapa tsa sebelisoa hape e le lihlahisoa tse ling tsa pampiri.

Mechini ea khatiso ea pampiri ea litšila e sebelisoa hangata liindastering tse joalo ka khatiso ea likoranta, ho paka le lisebelisoa tsa ofisi. Li thusa ho fokotsa bongata ba litšila tse romelloang litsing tsa lithōle le ho khothaletsa mekhoa e tsitsitseng ka ho tsosolosa lisebelisoa tsa bohlokoa.

Mochine oa khatiso oa baling oa pampiri ea litšila ke mochini o sebelisoang litsing tsa ho tsosolosa ho kopanya le ho hatella litšila tse ngata tsa pampiri hore li be libale. Mokhoa ona o kenyelletsa ho fepa pampiri ea litšila ka har'a mochini, ebe o sebelisa lirolara ho hatella thepa le ho e etsa libale. Mechine ea khatiso ea baling e atisa ho sebelisoa libakeng tsa ho tsosolosa, 'masepala le lisebelisoa tse ling tse sebetsanang le pampiri e ngata ea litšila. Li thusa ho fokotsa bongata ba litšila tse romelloang litsing tsa lithōle le ho khothaletsa mekhoa e tsitsitseng ka ho tsosolosa lisebelisoa tsa bohlokoa

Sehlahisoa sa pampiri ea litšila ke mochini o sebelisetsoang ho kopanya le ho hatella pampiri e ngata ea litšila hore e be bale. Mokhoa ona o kenyelletsa ho fepa pampiri ea litšila ka har'a mochini, ebe o sebelisa lirolara ho hatella thepa le ho e etsa libale. Lisebelisoa tsa pampiri ea litšila li atisa ho sebelisoa libakeng tsa ho tsosolosa, limmasepala, le lisebelisoa tse ling tse sebetsanang le palo e kholo ea pampiri ea litšila. Li thusa ho fokotsa bongata ba litšila tse romelloang litsing tsa lithōle le ho khothaletsa mekhoa e tšoarellang ka ho sebelisa lisebelisoa tsa bohlokoa hape.

waste paper baling press ke mochini o sebedisoang ho kopanya le ho hatella matlakala a mangata hore e be dibale. Mokhoa ona o kenyelletsa ho fepa pampiri ea litšila ka har'a mochini, ebe o sebelisa lirolara tse futhumetseng ho hatella thepa le ho e etsa libale. Mechine ea ho hatisa pampiri e litšila e atisa ho sebelisoa libakeng tsa ho tsosolosa, 'masepala le lisebelisoa tse ling tse sebetsanang le palo e kholo ea pampiri ea litšila. Li thusa ho fokotsa bongata ba litšila tse romelloang litsing tsa lithōle le ho khothaletsa mekhoa e tsitsitseng ka ho tsosolosa lisebelisoa tsa bohlokoa.

Mochini oa khatiso oa li-waste paper baling press ke karolo ea lisebelisoa tse sebelisoang ho khutlisetsa litšila ka libaleng. Ke sesebelisoa sa bohlokoa ts'ebetsong ea ho tsosolosa, kaha e thusa ho fokotsa bongata ba litšila tse romeloang libakeng tsa ho lahlela lithōle le ho khothalletsa mekhoa e tsitsitseng ka ho tsosolosa lisebelisoa tsa bohlokoa. Sehloohong sena, re tla tšohla molao-motheo oa ts'ebetso, mefuta ea mochini oa khatiso oa pampiri ea litšila, le lits'ebetso tsa ona.

Molao-motheo o sebetsang oa mochini oa khatiso oa baling oa litšila o batla o le bonolo. Mochini o na le likarolo tse 'maloa moo pampiri ea litšila e feptjoang ho eona. Ha pampiri ea litšila e ntse e tsamaea ka har'a likarolo, e hatelloa le ho hatelloa ke li-roller tse futhumetseng, tse etsang li-bales. Libale joale li aroloa ho litšila tse setseng tsa pampiri, tse ka sebelisoang hape kapa tsa sebelisoa hape e le lihlahisoa tse ling tsa pampiri.

Mechini ea khatiso ea pampiri ea litšila e sebelisoa haholo liindastering tse kang khatiso ea likoranta, ho paka le thepa ea ofisi. Li thusa ho fokotsa bongata ba litšila tse romelloang litsing tsa lithōle le ho khothaletsa mekhoa e tsitsitseng ka ho tsosolosa lisebelisoa tsa bohlokoa. Ho feta moo, li ka boela tsa thusa ho boloka matla le ho fokotsa litšenyehelo bakeng sa likhoebo tse sebelisang lihlahisoa tsa pampiri.

E 'ngoe ea melemo ea bohlokoa ea ho sebelisa mochini oa khatiso oa pampiri ea litšila ke hore o ka thusa ho ntlafatsa boleng ba pampiri e nchafalitsoeng. Ka ho kopanya pampiri ea litšila ka libale, ho ba bonolo ho tsamaisa le ho boloka, ho fokotsa kotsi ea tšenyo le tšilafalo. Sena se nolofalletsa likhoebo ho sebelisa lipampiri tsa tsona hape le ho netefatsa hore li khona ho hlahisa lihlahisoa tsa pampiri tsa boleng bo holimo

Qetellong, mechine ea khatiso ea baling ea pampiri e litšila ke sesebelisoa sa bohlokoa ts'ebetsong ea ho tsosolosa. Li thusa ho fokotsa bongata ba litšila tse romelloang litsing tsa lithōle le ho khothaletsa mekhoa e tsitsitseng ka ho tsosolosa lisebelisoa tsa bohlokoa. Ho na le mefuta e 'meli ea mantlha ea mochini oa khatiso oa pampiri ea litšila: moea o chesang le oa mochini, 'me o sebelisoa haholo liindastering tse kang khatiso ea likoranta, ho paka le lisebelisoa tsa ofisi. Ka ho sebelisa mochini oa khatiso oa pampiri ea litšila, likhoebo li ka ntlafatsa boleng ba pampiri ea tsona e sebelisoang hape le ho fokotsa tšusumetso ea tsona tikolohong.